Have you tried to generate a complicated shaped item but tend to not find a ideal developing process? Your search is over, due to the fact the art of Rotomolding has arrived in order to save the day. Rotational Molding, often known as rotational molding or rotocasting, is actually a production process where a hollow product is developed by heating system and turning a fungus filled up with molten plastic-type. This innovative approach will provide you with a perfect possibility to shape your ability to succeed by switching your styles right into a marketable actuality. In this particular blog post, we shall sophisticated on the skill of Rotomolding as well as its advantages.

Rotomolding is the best selection for manufacturing hollow products with complicated shapes. For its simplified production approach, it offers quite a few benefits over traditional methods. For starters, it allows you to design and style merchandise with some other shapes, for example spheres, cubes, and pyramids, with easy surface areas without having joints or seams. Consequently it is possible to manufacture items in a bit, which lowers the necessity for further components and set up. Additionally, the process is suitable to various types of plastic-type material materials which can be tough and fit to offer long-term application.

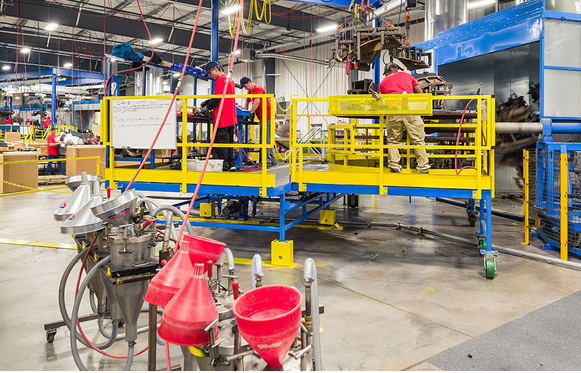

The procedure of Rotomolding is straightforward and straightforward. Very first, a mold is produced from the shape of your required item, and it’s then jam-packed into a Rotomolding equipment. Secondly, a fungus is warmed up to a particular temperatures, the custodians in the unit load the plastic-type resin from the fungus and after that spin the mold in various instructions, generating the plastic-type material substance itself across the mildew. After cooled, the fungus is launched, as well as the closing product is retrieved. This developing method is not only handy but additionally guarantees how the product or service molded is resilient and strong than usual.

Rotomolding’s program is just not set and may be used in various industries. It might, for instance, mildew sizeable tanks beneficial in positioning liquids or chemicals needed inside the gardening market. In addition, Rotomolding products are in high demand for usage in gasoline tanks, water storage space tanks, play ground equipment, and cleanliness. Ever since the production is customizable to suit various features, it is the smart choice of molding to consider.

Simply speaking:

In In a nutshell, Rotomolding is an craft which offers a solution to transforming sophisticated styles into truth. It is actually a ideal developing process for creating hollow goods with sophisticated designs. The process is straightforward, practical, and suitable in various businesses with assorted specifications. With Rotomolding, you can be assured of the great-high quality product that is tough, and extended-enduring at the lowered charge. Together with the positive aspects and applications mentioned above, it’s apparent that the skill of Rotomolding is actually a needed expense for virtually any company which requires the development of hollow formed merchandise for its development and enlargement.